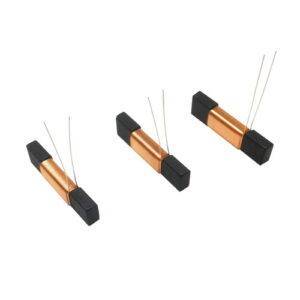

Smart pen coils, also known as inductors, are magnetic rod inductor coils wound with insulated wire. They are electronic components that generate self-inductance using one or multiple turns of wire. The smart pen coil has a special magnetic core, which is cylindrical in shape and also called a rod or R-rod. Due to its smooth cylindrical structure, it cannot be directly wound and fixed onto the body. In the production process of smart pen coil manufacturers, it is usually done using CNC coil winding machines. The coil is first formed and wound, and then the magnetic rod is inserted into the coil.

Advantages of this production process by smart pen coil manufacturers include:

With the help of CNC coil winding machines, specific turns can be accurately wound.

The smart pen coil is flat, and the legs are straight.

High efficiency, high production yield, and stable quality.

First, the enameled wire is passed through the tin groove, and the total length of the coil to be wound and the leg length are calculated. The legs are first soldered at both ends, and then winding is done using a mold head. The impregnation and winding are completed in one step, reducing costs. At the same time, the process of soldering before winding avoids the occurrence of coil short circuits due to soldering depth.

Currently, most smart pen coil manufacturers adopt the process of forming the coil first and then inserting the rod, as it is cost-effective and can adapt to most models. There are also a few automatic rod insertion machines available on the market that can directly produce finished rod inductors. Coil formation, wire insertion, adhesive bonding, and baking can be done in one step, but it requires strict dimensional requirements for the magnetic core. Moreover, it is not suitable for other models and can only be used for specific models. Additionally, there are equipment purchasing and maintenance costs involved.